Our activities & our expertises

Our activities

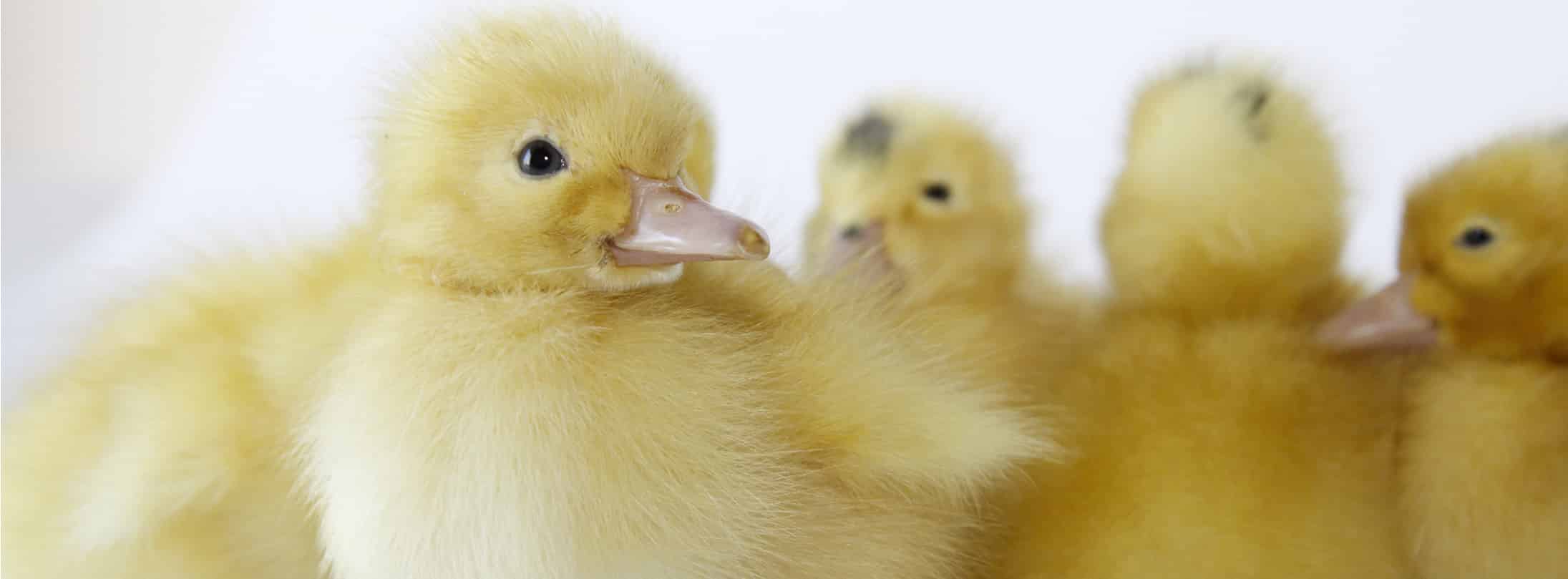

Waterfowls’ multiplication process : hatching

Hatching, Orvia’s core business, is the production and sale of day-old birds. Hatching eggs are collected from the breeding farms and brought every week to Orvia’s hatcheries for incubation. After hatching, the day-old birds are delivered to Orvia’s customers’ farms.

To meet the biosecurity and animal welfare requirements, Orvia continuously invests in the improvement of its hatcheries. For example, 8 million has been allocated to the modernization and development of the Sèvre Maine Hatchery in Deux-Sèvres, between 2021 and 2022. It is now one of the most modern facilities of the Group, with state-of-the-art industrial equipment and a production capacity of 180,000 ducklings per week.

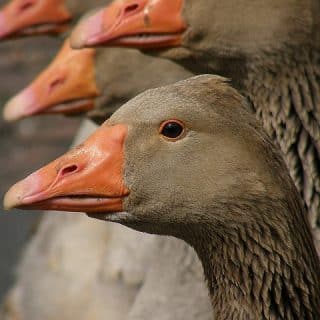

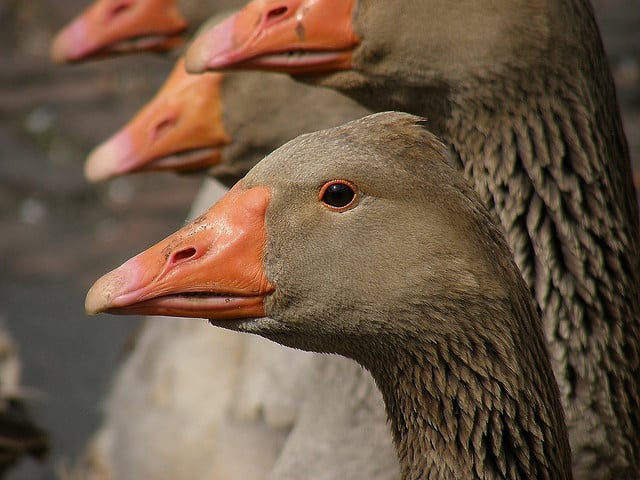

Waterfowls’ selection

Primary breeding is a specialised activity within the group and comprises selecting the best breeding animals from large populations. These animals will create the next generation. Orvia has been selecting geese and ducks in this way for over 40 years.

All breeding lines are audited by SYSAAF (French poultry and aquaculture primary breeders’ union) to check that they comply with the required standards. The Orvia research program allows for continuous improvements in performance in line with market developments, animal welfare and the expectations of customers and end consumers.

Today, the performance of Orvia’s products enables the group to be the leader in the French market. As a result, 75% of Mule ducks and 65 % of Muscovy ducks sold in France were from Orvia strains. The Orvia’s Pekin duck represents 65 % of the european volume sold and nearly 20 % in Asia (excluding China). The group exports to over 40 countries worldwide.

A research program in Selection: the Black Soldier Fly (Hermetia Illucens)

Since 2018, through our Cycle Farms subsidiary, we have been selecting black soldier fly lines for their optimal zootechnical characteristics. The Group’s experience in waterfowls’ breeding is a key success factor in advancing such research programs.

To this end, we draw on the expertise of SYSAAF to improve the performance of our animals.

Orvia’s aim is to promote products that will improve our customers’ economic performance and the quality of their finished products.

Further information available on Cycle Farms’ website

Our expertise

Technical

Orvia’s technicians are experts in animal production. They guarantee the good management of our livestock.

Their technical know-how and their excellent understanding of the requirements for each of the species we offer enable our products to obtain technical and economic results in line with market expectations and trends.

Orvia’s technical department continuously strives to promote the modernization of farms, both to optimize the performance of the animals, provide the best environment for the animals and to improve working conditions, while satisfying the expectations of customers.

Health

In order to avoid any risk of contamination and to guarantee customer satisfaction, Orvia makes every effort to protect its livestock and production sites. Health and biosecurity are the cornerstone of our business.

The objective is to protect against any bacteriological or virological risk.

The internal biosecurity audits allow us to regularly check and ensure the implementation of the good practices published by the sanitary rules and in particular the requirements of the SNA* charter (Syndicat National des Accouveurs i.e., The National Union of Hatcheries) that Orvia is committed to follow.

Hygiene trainings are provided by internal or external services (QHSE department, veterinarians), to reiterate the rules of good professional practices in our farms and hatcheries (SAS 3 zones, sanitary empties, rendering management, disinfection, secure transportation, signposting, etc.).

* Orvia is considering the design and implementation of a similar hygiene charter, specifically related to the activity of insects.

Logistics

Orvia has its own logistics fleet, made up of experienced drivers trained in the transport of live animals, in compliance with stringent animal welfare rules.

In order to limit the risks of contamination and/or transmission of pathogenic agents from one site to another, all delivery and hatching egg collection vehicles are equipped with an on-board disinfection system.

The group has its own logistics fleet to make deliveries to customers.

Animal welfare

At the heart of our activities, animal welfare is a key issue for the future of our business and our place in society. On a daily basis, we work to provide an environment that is more and more conducive to the animal’s development and to ensure its hygiene and well-being. This commitment translates into the breeding of physically and physiologically healthy animals.

We implement our animal welfare policy, in hatcheries and in breeding farms to ensure that the animals can meet their 5 basic needs, which define them as sentient beings:

- Physiological needs: adequate feeding and watering;

- Sensory needs: respect for animal sensitivity;

- Environmental needs: animal comfort;

- Veterinary needs: animal health;

- Social needs: expression of natural behavior.

We have set up an Orvia Animal Welfare procedure which is a result of a long research work that integrates humans and animals. The goal is to improve our breeding practices (the environment, quality of handling, and better satisfaction of the needs of the farm animal, etc.).

A specific training has been developed with the help of our veterinarians and is implemented in our farms and hatcheries to verify and standardize the compliance with our BEA (Animal Welfare) good practices.